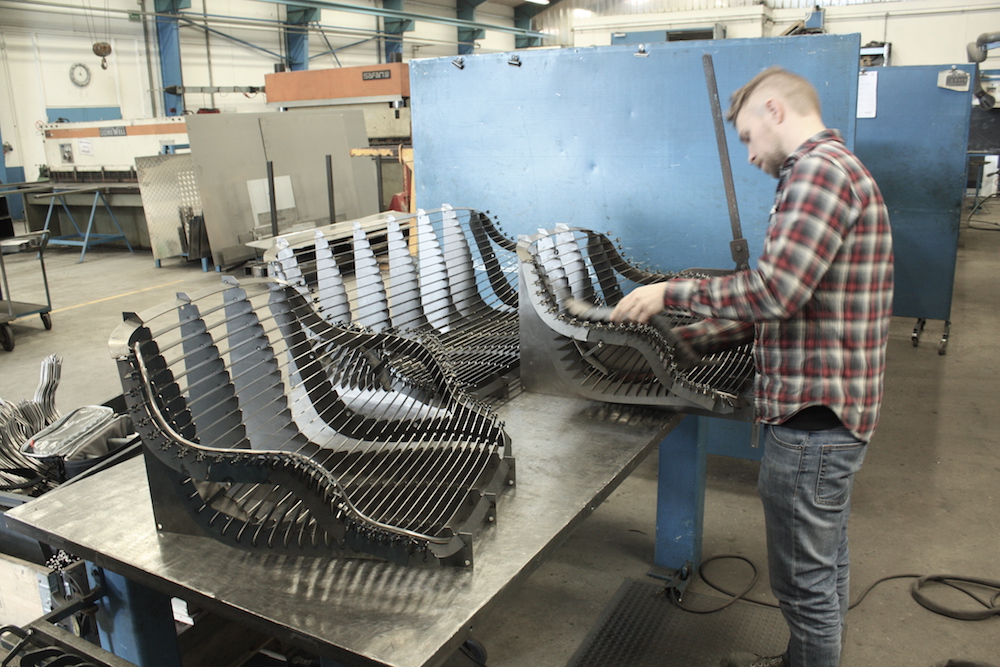

At one point, around the last part of 2012, Christian was doing his blacksmith work in his sister’s henhouse. Surrounded by chicken crap and bad lighting and with no heat and no useful tools or machinery he was shaping the skeleton of the Wire Collection – the iron frame.

But it wasn’t easy.

”I kept getting zapped by electricity,” Christian tells me.

And now it gets a bit complicated for a writer girl like me. But the thing is that when you are welding, you need to have electricity going through whatever you’re welding. You need a ground cable connected to your subject, so that you’re creating a closed electric circuit. Usually you’d put the ground cable on the table, which is normally made of steel. And then that’s all you have to do.

But Christian was working at a wooden garden table, and since wood does not conduct electricity, he had to connect the ground cable to the subject every time he wanted to work.

“When you try to weld without the ground cable, you can get a small schock from the initial spark. That’s not too bad, but still makes you kind of nervous, when you tried it enough times. However, what you really don’t want to do is touch the ground cable. Then you get around 100 ampere through your body and it’s not really a lot of fun anymore.”

Jasper, on the other hand, was not bothered by fast electricity. Quite the opposite you could say. Jasper was at home in his two-bedroom apartment. From here he was experimenting with a beautiful, but very old Singer sewing machine – a secondhand buy from some relatives of a deceased stranger. It was also at this time that Jasper managed to sew the first full-grain leather upholstery for the Wire chair.

”It took a few days,” he says smiling.

The story of the two entrepreneurs truly had its bohemian ”you-gotta-crawl-before-you-walk” moments. But there is nothing sentimental about it for Jasper and Christian. Those were the circumstances, the actual options, if they wanted to pursue their dream. Even if a henhouse and an old sewing machine were to get them there.